FAQs

Question #1: How is an

EVM CHP-unit developed?

For

ex. Hotel Sonnschein

Question #2: Is a CHP-unit by EVM profitable for me?1. Recording of customer requirements

2. Planning

3. Applications for subsidies

4. Production of the specified EVM CHP-unit

5. Assembling engine and alternator

6. Piping

7. Storage facility

8. Control systems and electronics

9. Wiring and testing

10. Noise insultation

11. Installation and initial start-up on site

1. For renewable energy carriers

2. For fossil energy carriers

Question #1: How is an EVM CHP-unit developd?

1. Recording of costumer requirements: (to the top)All important data of the customer are recorded (electricity bills, heating and oil consumption etc.). Existing energy and control systems will be taken into consideration. A free quick check will be worked out for our costumer.

Consequently, detailed planning and its projections are worked out for the costumer. With that, all weaknesses in the existing system and its savings potential will be evaluated.

Furthermore, the customized EVM CHP-unit including the combustion engine is designed. In addition, our partner BP GAS AUSTRIA is already designing the complete liquid gas storage facility for the CHP-unit, and furnishes the necessary know-how for the gas supply logistics. Detailed and specific economic calculations are handed to the customer and various aspects are discussed.

3. Application for subsidies (Austria only): (to the top)

Upon signing of the contract, all necessary formalities for subsidies are done by EVM.4. Production of the specified EVM unit: (to the top)

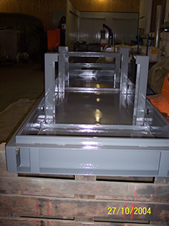

EVM engineering builds frames, water cooled mufflers, exhaust heat-exchangers.

At the same time, the engine is designed and built by EVM Motorenbau. Because of very particular energy usage peaks of this hotel, a stoichiometric (Lambda 1) Gas Otto aspirated engine with optimal ignition and fuel mixture is prepared. Lowest emissions, as well as good part-load characteristics and minimal service cost, guarantee an economic operation of the CHP-unit.

_klein.png)

_klein.png)

_klein.png)

_klein.png)

5. Assembling engine and alternator: (to the top)

Engine and alternator are combined and put as one unit on the prepared frame.

Meanwhile, the prefabricated pipes are fitted and mounted on the CHP-unit.

7. Storage facility: (to the top)

At the same time, BP Gas Austria installs the storage facility.

8. Control systems and electronics – the EMV unit gets its brain power! (to the top)

Considering the existing energy system of this hotel, the specific control system and the software for the CHP-unit are built and programmed.

9. Wiring and testing: (to the top)

The EVM unit is wired and tested.

10. Noise insulation: (to the top)

The noise insulation cover is mounted, and final adjustments are made.

11. Installation and initial start-up on site: (to the top)

The unit is installed and ready for operation.

From now on, the CHP-unit will be monitored by the EVM service team 7 days a week, and, all necessary maintenance will be performed.

Question #2: Is a CHP-unit by EVM profitable for me?

1. For renewable energy carrier: (to the top)● You plan or operate a biogas facility?

● You want to produce power and heat from a land fill?

● You operate a waste water treatment plant?

● You have a specified energy carrier (special fuel)?

● You produce ethanol or similar and want to generate power?

2. For fossil energy carriers: (to the top)

You operate:

● a hotel, and/or restaurant?

● a production facility or administration building with high energy consumption?

● a clinic?

● an indoor swimming pool?

● a sport or wellness facility?

You have:

● a ratio of heat/cooling to electricity of about 3:1?

● electricity and heating/cooling costs of at least Euro 25,000 annually?

You want to:

● reduce your energy cost?

● acquire a future source of income?

● contribute to the environment?

● be independent from conventional sources?

... then a CHP-unit by EVM is profitable for you!

. |